The BM team unleashing the #15 PJ car at Bridgehampton in 1969.

Picture courtesy David M. Bauer/Sam Colman.

The truth about Bud Moores engine building secrets and others - Part 3

Now we get a real deep look inside and an idea about ramp trucks going 90mph hauling T/A race cars! They really even push from behind.

Enjoy reading - Wolfgang

Did Bud Moore use a roller rockers on the Tunnel-Port 302 engines?

I did not work with BM on the tunnelport 302. My best guess is that SCCA and NASCAR rules wouldn't allow the use of roller rockers

Did BM use the Ford roller fulcrum rocker arms on the '69 Boss 302 engines or just on the '70 season engines?

Picture Car Life, Aug. 1969, but shown is a Shelby T/A

Racing Engine 1969.

We used the fulcrum roller rocker arms for 1969 and 1970. The rules stated that they had to be the factory rockers but didn't say that we could not use roller bearings for the fulcrum. They were Torrington needle bearings.

Was a full roller rocker used and when?

The full rocker arms were not used on the Boss 302 for Trans Am racing.

Did BM raise (fill) the bottom of the intake ports in the Boss 302 cylinder heads and intake manifold or keep the regular tall height of the ports?

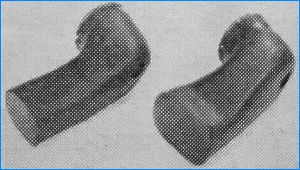

Pictures shows not BM, but Shelby T/A Racing port pattern

(left) and Stock 302 (right). Smaller port actually has same flow, but

better velocity for low speed power. (Car Life, Aug. 69)

In 1969, we used ported and polished heads from Air Flow Research. Shelby said they were the best and Ford went with them. Over the winter, a Ford fuel specialist named Denny Woo ( he did the fuel systems for the Ford Indy car project), had a set of heads made so that he could change intake port size. He hand messaged removable ports so that we could change port sizes. We could raise or lower the floor, or raise or lower the roof, or narrow the port completely. We used the smaller ports with a raised floor and roof to get more speed into the cylinders due to using the mini-pleneum manifold.

What connecting rods did BM use on the Trans-Am Boss engines?

We used what was known as Indy rods. They were steel rods and weighed about 2000 grams! They were strong and were to be like the rods that were used in Ford's Indy car project. We couldn't use aluminum rods because of the rules. These rods were longer than the stock rods.

Any general tricks you may have for builders of engines such as the 289 .... and 302 BOSS from your professional view?

Make sure that your oil system is in top notch condition because Fords always have oiling problems. We used a double pump out of the 530 Ford truck engines. Remember, Ford gave us parts that the public could not get. We used copper rings to seal our cylinders, "O" rings to seal water passages and silicon to keep the oil and water where they should be.

I am having a little problem with "tricks". I would say that you build the short block to accepted tolerances and the rules of your racing association. Make sure you degree your camshaft and work with the cam grinder on what you are trying to accomplish with the engine setup. Make sure you plan your build up so that you know what you are trying to accomplish and can communicate that to the people who you are buying the parts from and those doing the machine work. If you have to use stock rods, make sure that they are magnafluxed, polished, shot peened and use new rod bolts. Try to find the best machine shop that has the latest and best machine equipment and also has a knowledgeable staff. It would help you to have access to both an engine dyno and chassis dyno because then if you are making lots of horsepower on the engine dyno and you put it in the vehicle and the horsepower drops more than 25%, then you know that the drive train is soaking up a lot of power and you have a place to start looking for the lost power. I guess what I would need is specific questions and I'll try to answer them one at a time.

Thanks a lot, Edd, we may come back to this. BTW - having a D1ZM-6015-AA mexican block - I was told it is a stiffer block and was often used for export and preferred for modified engines. Can you enlighten me with the truth about the Mexican 302 block and the Motorsport 302 block?

I really can't give you any further information about the Mexican block other than what has already been written. It's a good block; the original Boss 302 blocks had 4 bolt mains and we had screw-in pipe plugs instead of the brass welch plugs. The Motorsport block is set up for a roller cam and lifters.

Any details you remember about the Bud Moore race hauler truck? Did you work on that engine as well as the cars? Which engine was installed and what was modified?

Ross Myers Bud Moore ramp truck at the LRP Vintage Fall Festival in 2002

Picture courtesy Steven Francis

I'm not quite sure of the questions. The trucks that hauled the race cars were Ford F350's with 390 V8's. They really hauled the race cars. After one of the trucks beat Bud and the Ford engineers back to the shop from Martinsville, VA, they put governors on them so that they couldn't go over 65 MPH. We were going to California, it was night and the CHP (California Highway Patrol) pulled us over. They said to the driver," Do you know you were going 90 f*****g MPH!?" The trucks were worthy of "hauling" the race cars.

Ross Myers Bud Moore ramp truck at the Lime Rock Festival 2002

Picture courtesy David M. Bauer

What did you do after the '70 season?

After the 1970 season I worked building engines and the Monday after Thanksgiving Bud called us into his office and told us that Ford had closed the program. So we were out of a job. My wife and I decided to move back to California and I became a Nissan technician. When Bud went back into NASCAR, I helped them on the pit crew when they came to California..

Thanks a lot, Edd for the moment. As I promised not to bother you to often, I'll keep collecting interesting questions and trying to create a ASK EDD section for a kind of knowledge database.

I'm quite flattered about the interest in my responses, guys. I'll be ready to answer some at least from time to time via Wolfgangs site.

Dear Gentlemen and gentle women - get staged for the extra site. We've already got some questions answered, but I have to find the proper structuring first to fill them in.

Update: Sorry for delays as usual (2009

- 2025 lasting)